Lambaran Busa Karét Kingflex Kandel 13mm

Diménsi Standar

| Diménsi Kingflex | |||||||

| Tkakeuheul | Width 1m | Width 1.2m | Width 1.5m | ||||

| Inci | mm | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Lembar Data Téknis

| Data Téknis Kingflex | |||

| Properti | Unit | Nilai | Métode Tés |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap cai | Kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Bagian 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Rating Seuneu | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indéks Sebaran Seuneu sareng Pengembangan Haseup |

| 25/50 | ASTM E 84 |

| Indéks Oksigén |

| ≥36 | GB/T 2406, ISO4589 |

| Panyerepan Cai,% dumasar Volume | % | 20% | ASTM C 209 |

| Stabilitas Diménsi |

| ≤5 | ASTM C534 |

| Résistansi jamur | - | Saé | ASTM 21 |

| Résistansi ozon | Saé | GB/T 7762-1987 | |

| Tahan ka UV sareng cuaca | Saé | ASTM G23 | |

Profil Perusahaan

Kingflex dipiboga kuKingway Group. Kingway diadegkeun dina taun 1979, éta mangrupikeun pabrik bahan insulasi munggaran di kalér walungan Yangtze di Cina.

Taun 1979, pupuhu Tongyuan Gao ngadegkeun WuHeHao Insulation Material Factory.

Dina taun 1996,Hebei Kingway Energy Saving Technology Co., Ltd diadegkeun.

Dina taun 2004,Hebei Kingflex Insulation Co., Ltd diadegkeun.

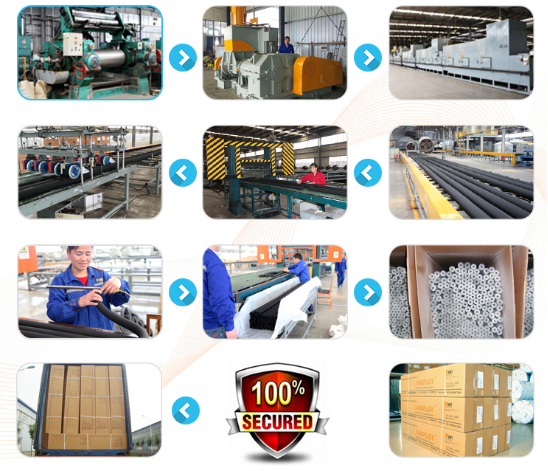

Jalur Produksi

KingflexKarétbusaBahanna nyaéta bahan insulasi panas anu lemes, pelestarian panas sareng konservasi énergi anu didamel nganggo téknologi canggih di bumi sareng jalur produksi kontinyu otomatis pinuh canggih anu diimpor ti luar negeri, nganggo karét butironitril kalayan kinerja pangsaéna sareng polivinil Klorida (NBR, PVC) salaku bahan baku utama sareng bahan bantu kualitas luhur sanésna ngalangkungan busa sareng prosedur khusus saterasna.

Aplikasi

Sertifikasi

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp