Insulasi Busa Karét NBR Sél Katutup

Panjelasan Produk

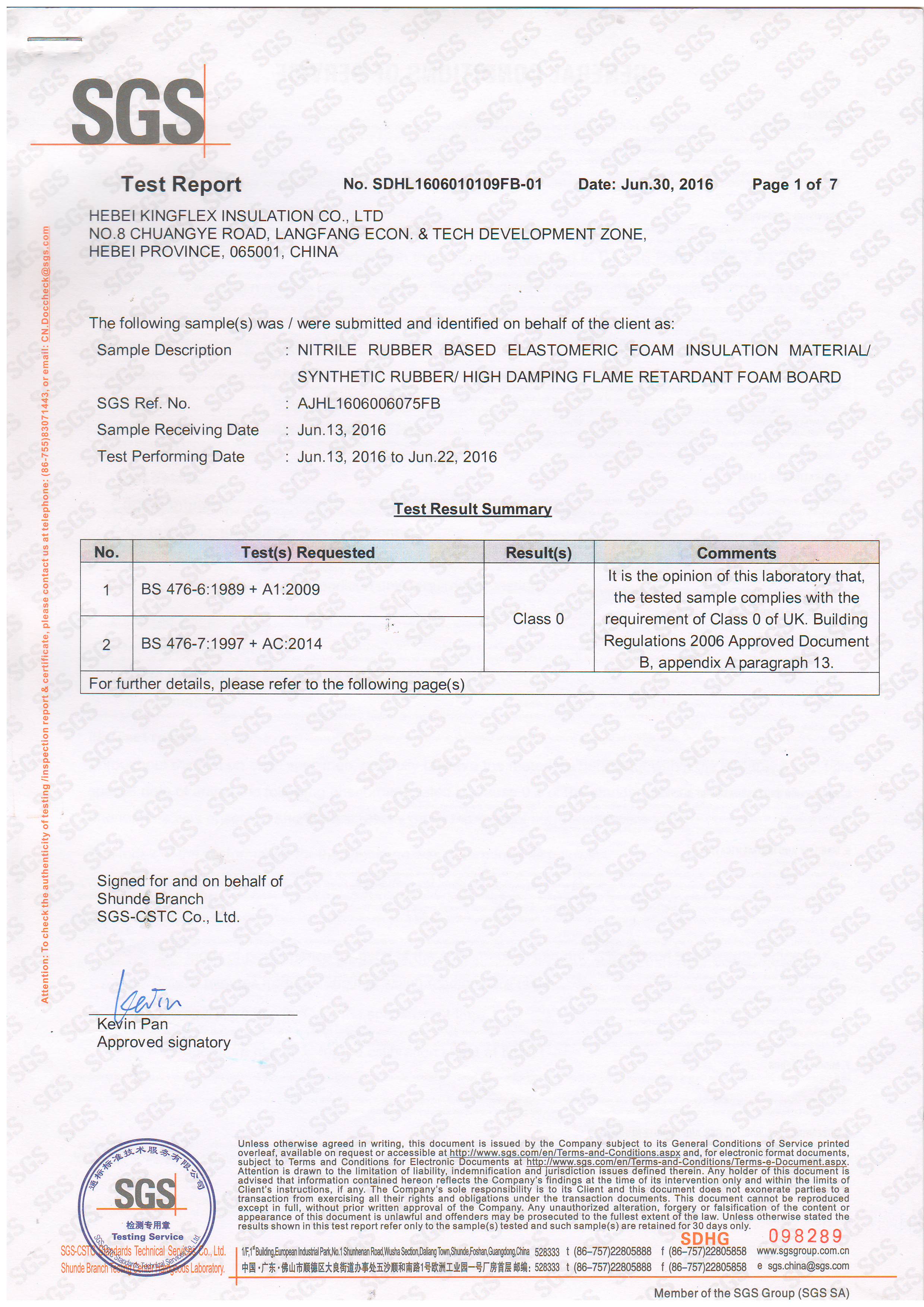

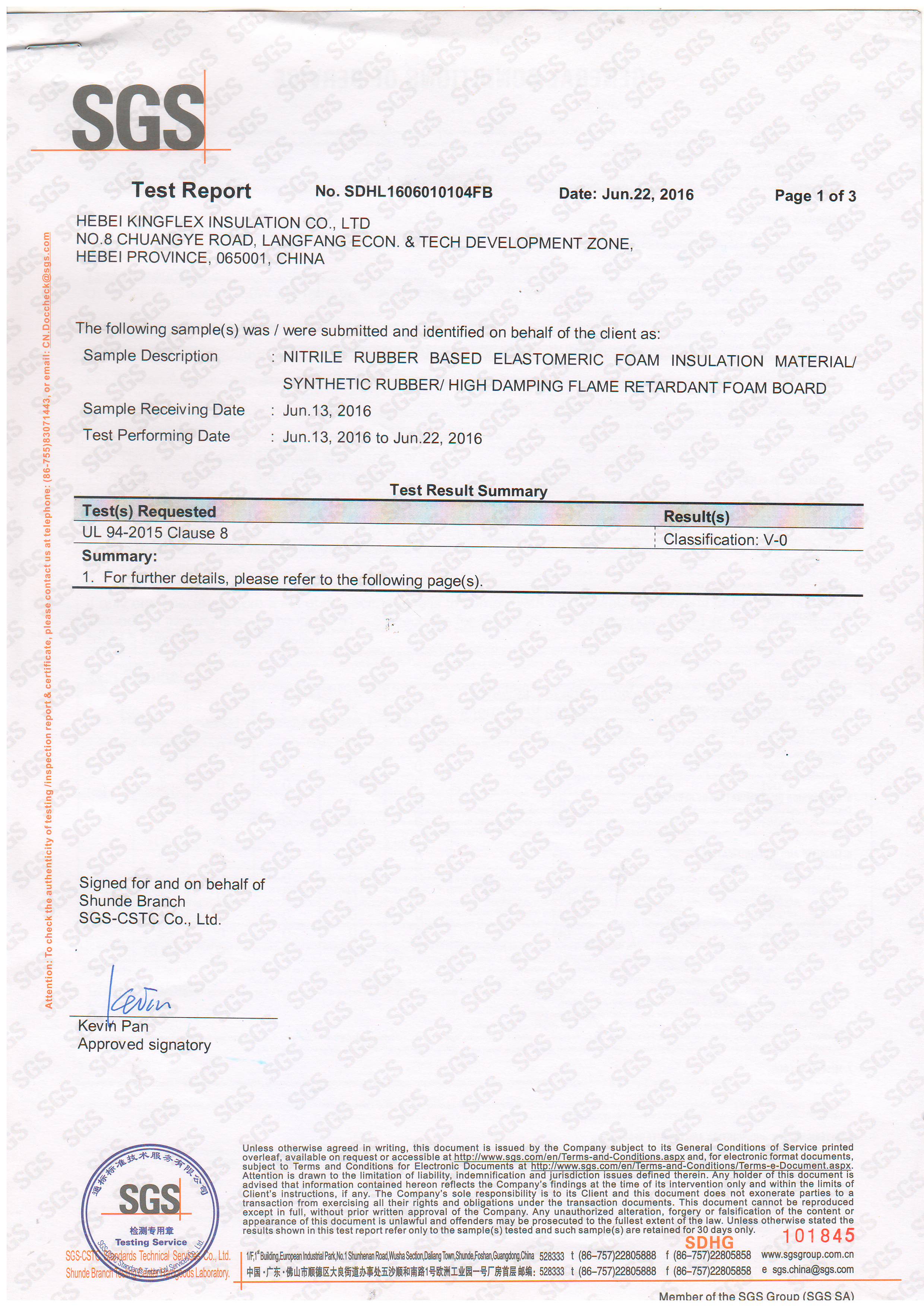

Métode tés standar peringkat seuneu anu dilakukeun dina kaayaan laboratorium anu dikontrol nyaéta ukuran bahan pikeun nyebarkeun seuneu dibandingkeun sareng standar anu dipikanyaho sareng henteu dimaksudkeun pikeun ngagambarkeun bahaya anu dipicu ku bahan ieu atanapi bahan naon waé dina kaayaan seuneu anu saleresna.

Diménsi Standar

| Diménsi Kingflex | |||||||

| Tkakeuheul | Width 1m | Width 1.2m | Width 1.5m | ||||

| Inci | mm | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung | Ukuran (P * L) | ㎡/Gulung |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Lembar Data Téknis

| Data Téknis Kingflex | |||

| Properti | Unit | Nilai | Métode Tés |

| Rentang suhu | °C | (-50 - 110) | GB/T 17794-1999 |

| Rentang kapadetan | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Permeabilitas uap cai | Kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Bagian 2 1973 |

| μ | - | ≥10000 | |

| Konduktivitas Termal | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Rating Seuneu | - | Kelas 0 & Kelas 1 | BS 476 Bagian 6 bagian 7 |

| Indéks Sebaran Seuneu sareng Pengembangan Haseup | 25/50 | ASTM E 84 | |

| Indéks Oksigén | ≥36 | GB/T 2406, ISO4589 | |

| Panyerepan Cai,% dumasar Volume | % | 20% | ASTM C 209 |

| Stabilitas Diménsi | ≤5 | ASTM C534 | |

| Résistansi jamur | - | Saé | ASTM 21 |

| Résistansi ozon | Saé | GB/T 7762-1987 | |

| Tahan ka UV sareng cuaca | Saé | ASTM G23 | |

Kauntungan Produk

♦ Kalenturan anu saé dina suhu anu handap

♦ Bersih, bébas lebu, gancang sareng gampang dipasang

♦ Konduktivitas termal anu handap

♦ Penampilan kualitas produk seragam anu saé

♦ Faktor résistansi uap cai anu luhur,>5500

Perusahaan Kami

Pameran Perusahaan

Sertipikat Perusahaan

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp